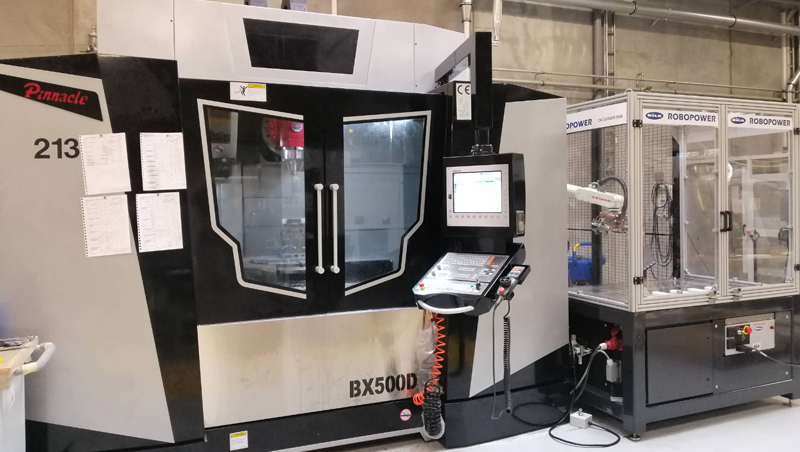

SV series

SV85/SV105

SV's Designed for Extra Value and Built for Optimum Performance

Box Way Series

Now you can get the right VMC's with the right features for extra heavy-duty machining, superior stability and excellent rigidity. Pinnacle box way SV series are quality constructed throughout for maximum performance dependability - year after year. If you expect a VMC that will provide higher machining efficiency to reduce production costs, then consider placing a dependable, heavy-duty Pinnacle SV series in your production line.

Features

- 850(1020) X 560 x 560 mm Travel

- Rapid Feedrate 20/20/20 m/min

- 10 HP Spindle Motor

- ISO40 Spindle Taper

- Spindle Speed 8,000 rpm

- 10,000 rpm (option), Direct drive 12,000 rpm (option)

- X, Y & Z Axis Box Way

- Features

- Specifications

- Accessories

- Quality Inspections

- Options

- Video

Features

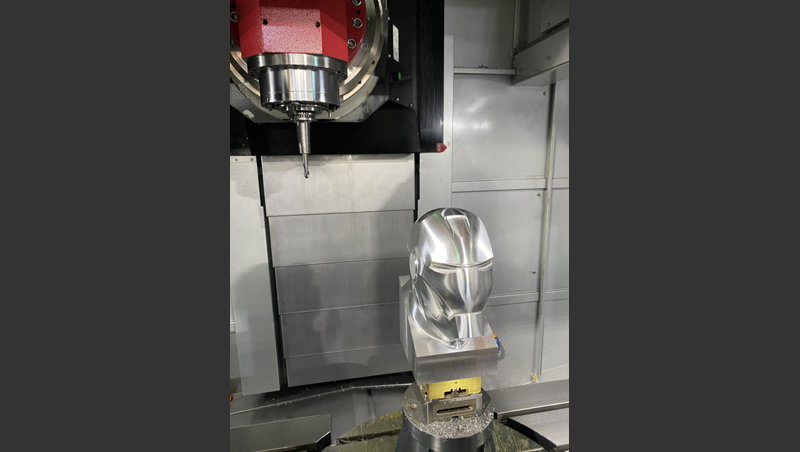

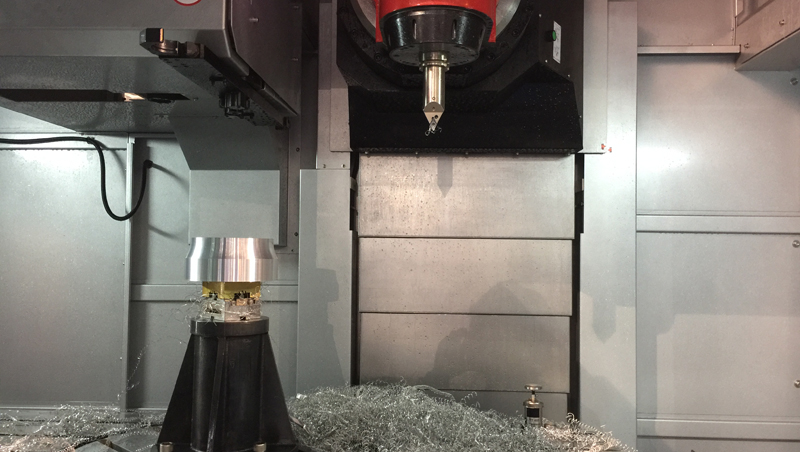

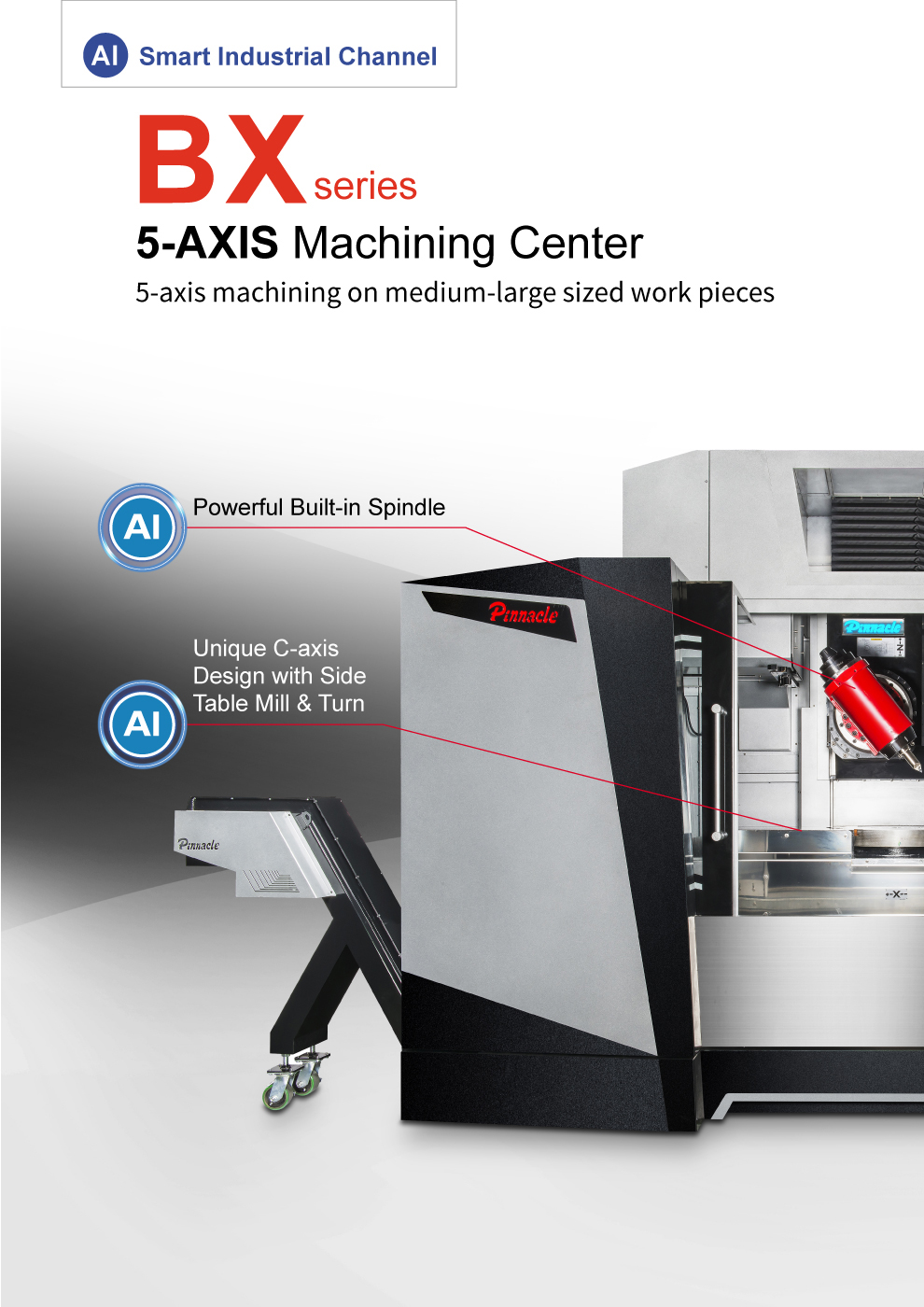

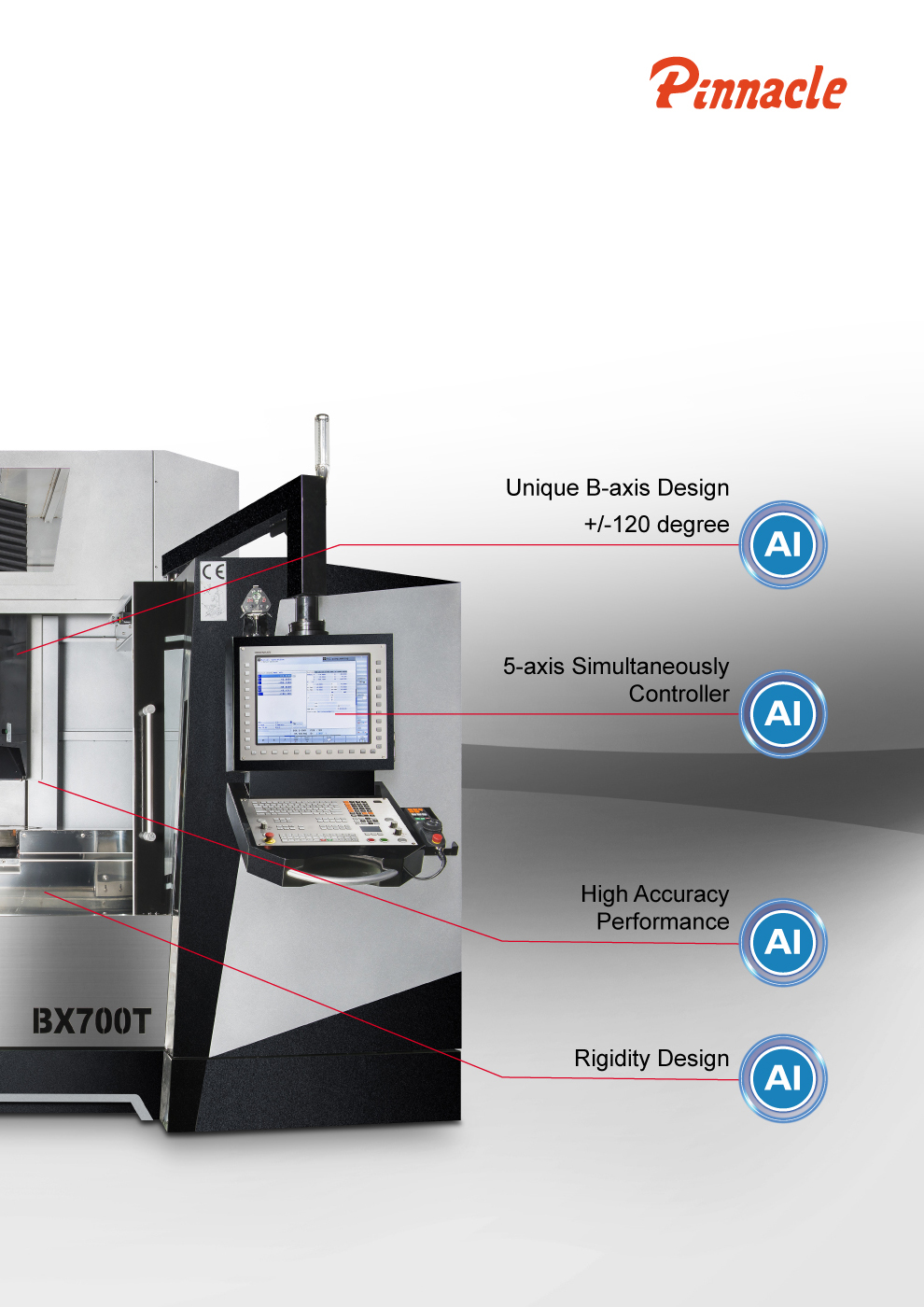

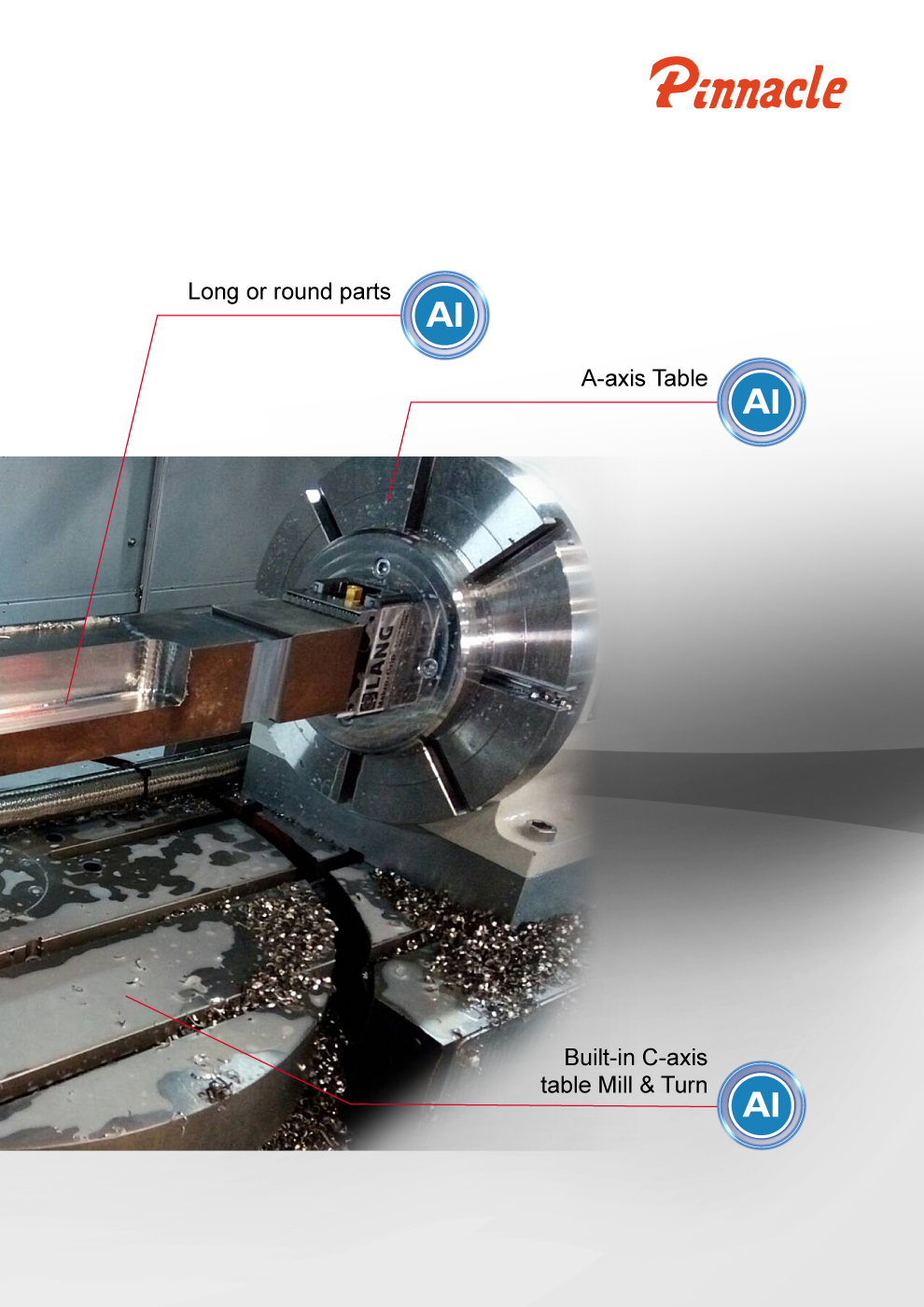

The Best Possible Structural Design

Rugged Construction Assures Optimum Rigidity and Stability.

The major structural parts are manufactured from high quality Meehanite cast iron (GB 300), tempered for stress relief with hardness over 190HB.

Box ways on the three axes. Way surfaces are hardened to over HRC55 with over 2 mm depth.

Three axes are equipped with class C3 and 36mm (SV85/SV105) and 40mm (SV116/SV126)diameter precision ball screws.

Taiwan Patent No.: 177230, China Patent No.: 416211

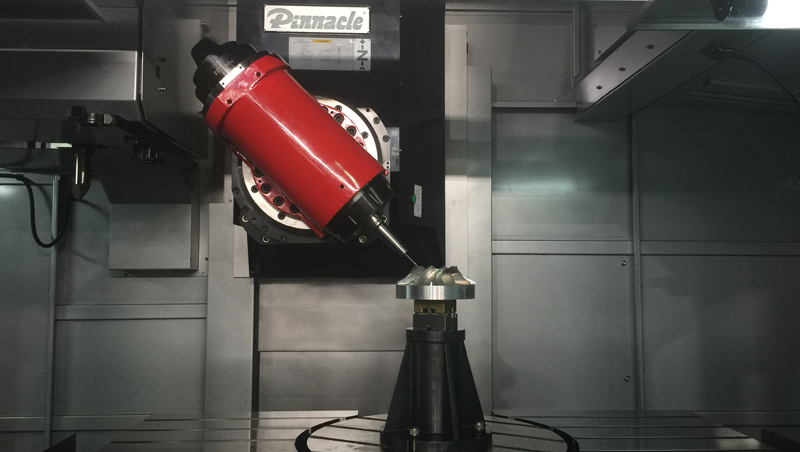

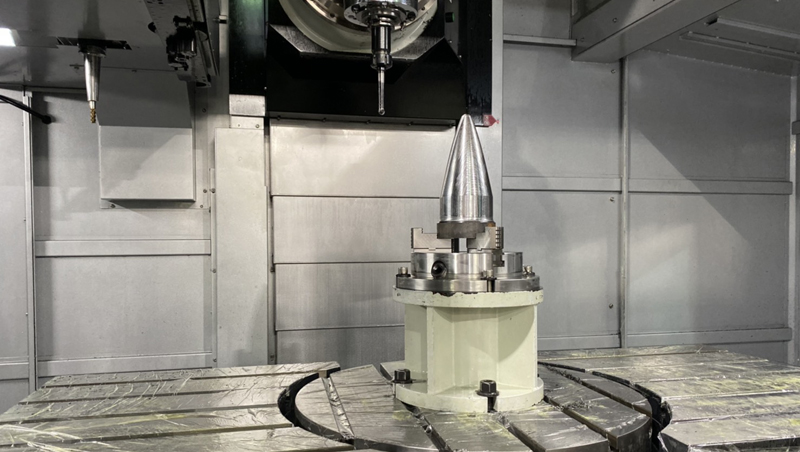

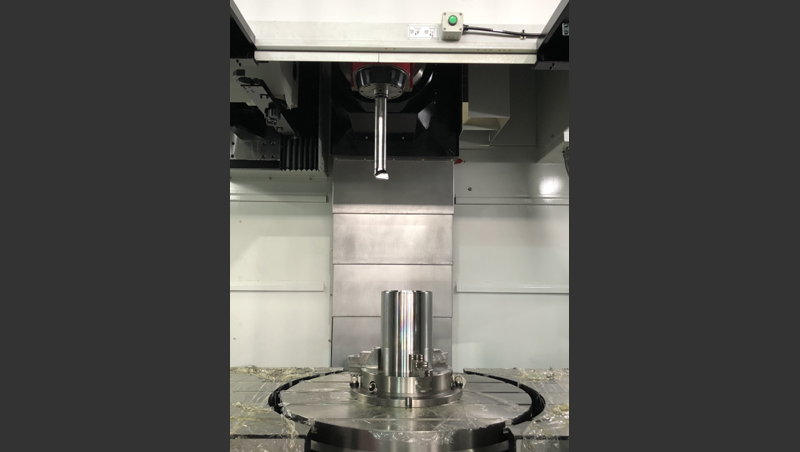

RIGID, PRECISION SPINDLE

ASSURES HIGH QUALITY MACHINING

- Supported by superior precision P4 class bearings, the spindle provides an extra wide range of machining capacity and high speed.

- Floating unclamping system assures tool unclamping force will not transmit to the spindle bearings. It provides stable tool clamping and unclamping with the spindle and extends the spindle bearings' life.

- The spindle is a cartridge-type.

- Choice of various spindle speeds - 8,000, 10,000 and 12,000 rpm.

- The circulating oil cooling system on the spindle head prevents thermal expansion and offers the best precision machining environment.

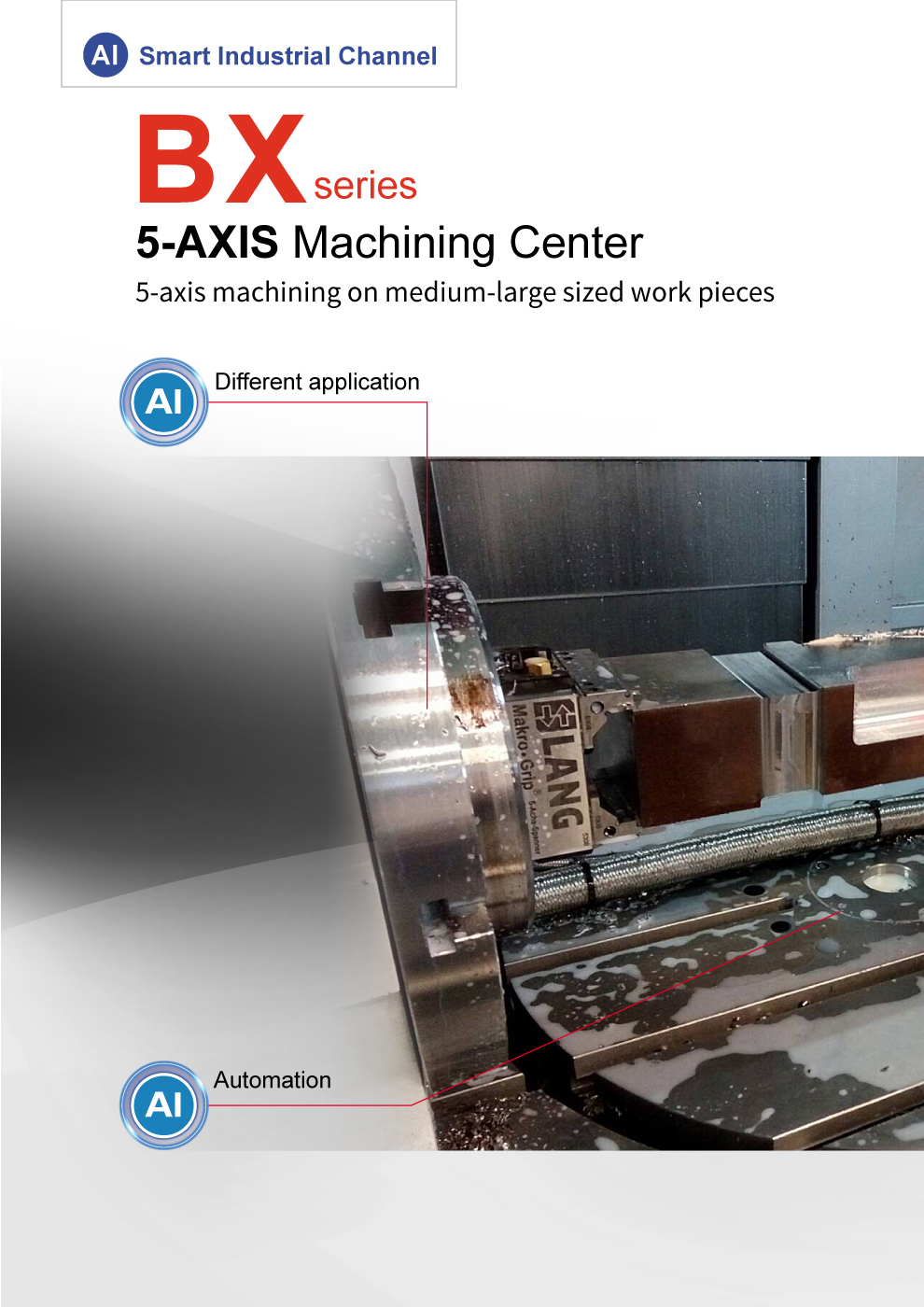

Chips Flushing Nozzles

Coolant flushing nozzles on rear inner wall of guard prevent jam of chips during operation.

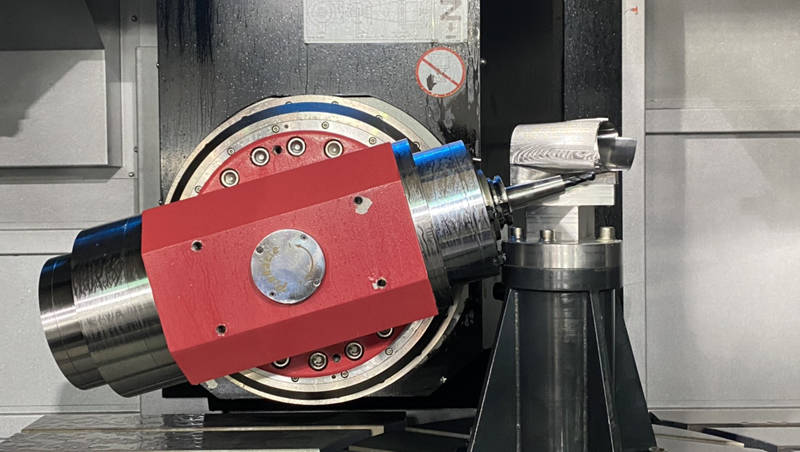

Couplings

Directly connected with ball screw and AC servo motors, the high precision flexible couplings offer the best rigidity and keeps the accuracy of axial linear assembly under high speed movement.

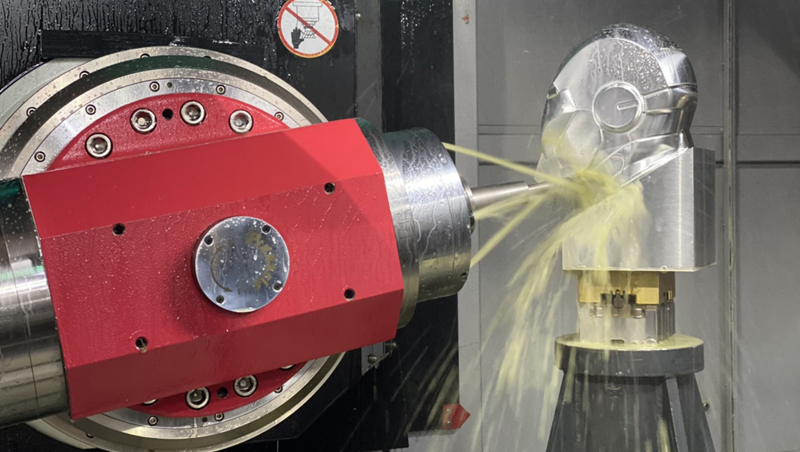

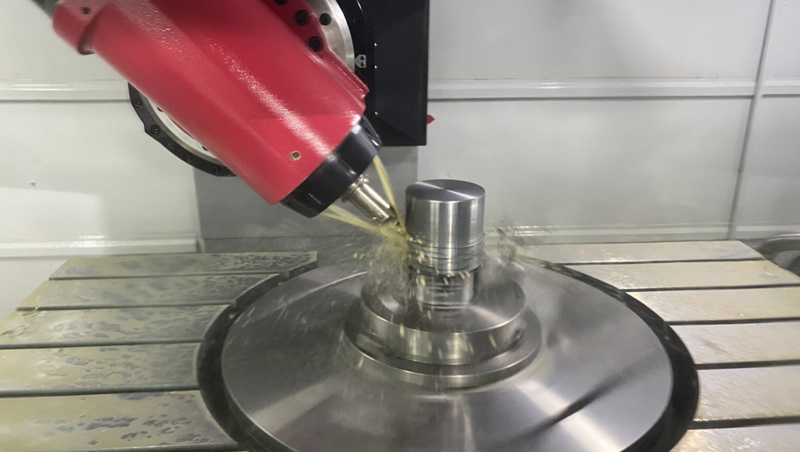

Coolants Jets Around Spindle

Improved cooling efficiency on workpiece.

Automatic Lubrication System

The Lubrication System automatically measures and accurately distributes the oil to the slide ways, ballscrews and bearings.

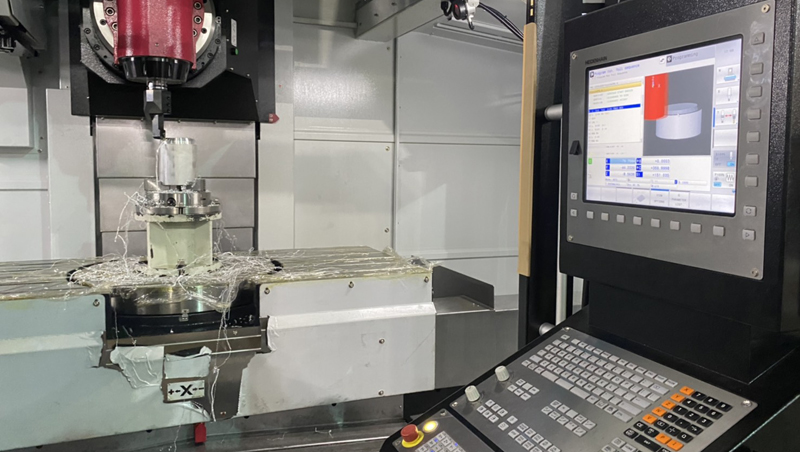

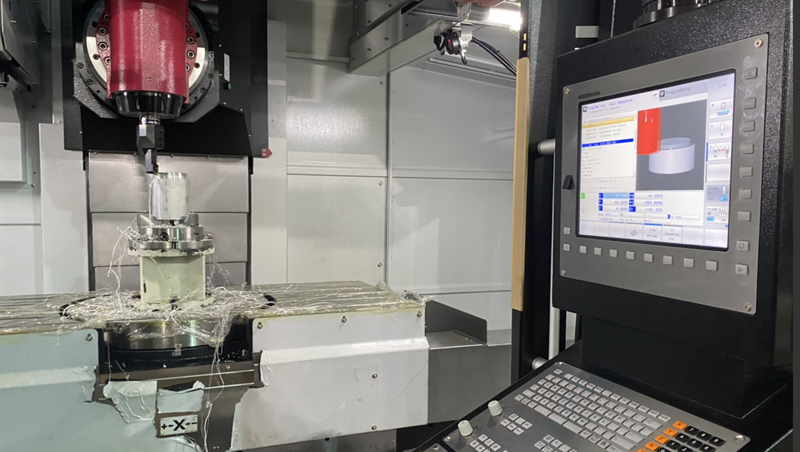

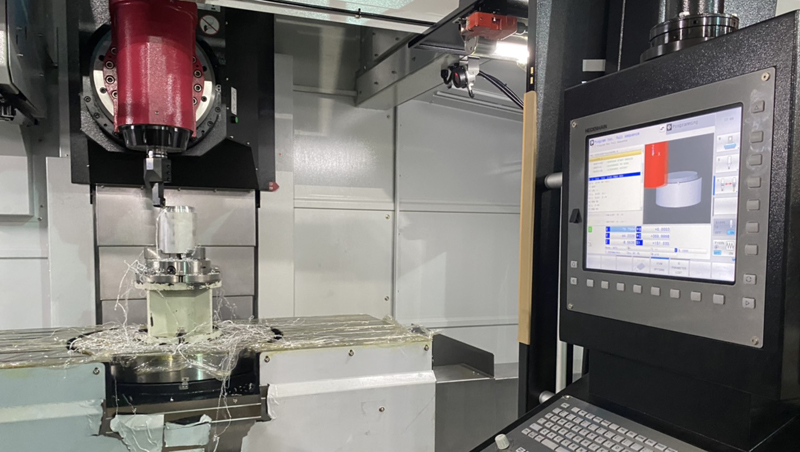

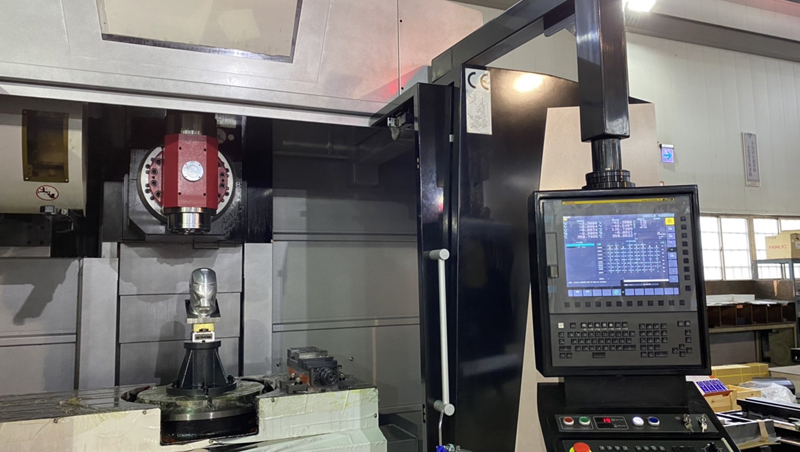

Control System

The centralized control panel employs a touch sensing screen for user-friendly operation. The humanized designed control panel has an elegant appearance. Various controllers can be chose - Mitsubishi, Heidenhain, Fanuc and Siemens.

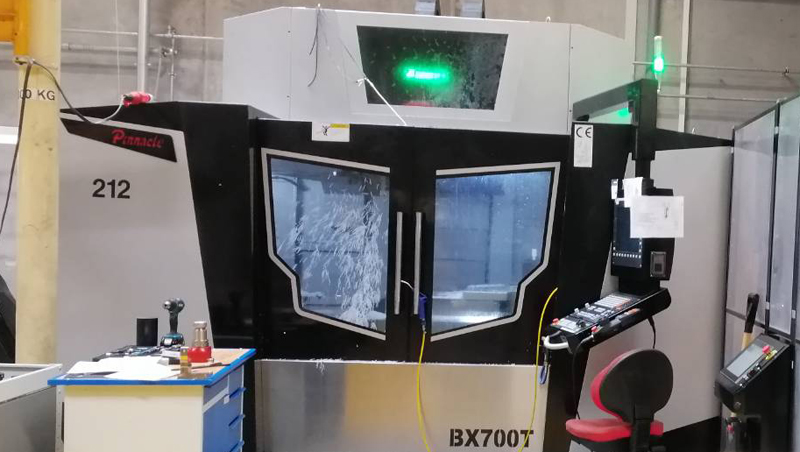

Splash Guard

The full-enclosed splash guard meets environmental protection and CE requirements. It offers users a comfortable working environment.

Specifications

| MODEL | SV85 | SV105 | |

|---|---|---|---|

| TABLE | |||

| Table Size (mm) | 1000 x 510 | 1200 x 510 | |

| Travel Ranges (X x Y x Z mm) | 850 x 560 x 560 | 1020 x 560 x 560 | |

| Max. Table Load (kgs) | 600 | 600 | |

| Spindle Nose to Table Surface (mm) | 100 ~ 660 | 100 ~ 660 | |

| T-slot (Width x Distance x Number mm) | 18 x 100 x 5 | 18 x 100 x 5 | |

| SPINDLE | |||

| Distance Between Column (mm) | ISO40 | ISO40 | |

| Spindle Inner Diameter (mm) | Ø60 | Ø60 | |

| Spindle Center to Column (mm) | 620 | 620 | |

| Spindle Speed (rpm) Belt | 60 ~ 8000(10000/12000) | 60 ~ 8000(10000/12000) | |

| Spindle Speed (rpm) Gear | L40 ~ 2000, H2001 ~ 8000 | L40 ~ 2000, H2001 ~ 8000 | |

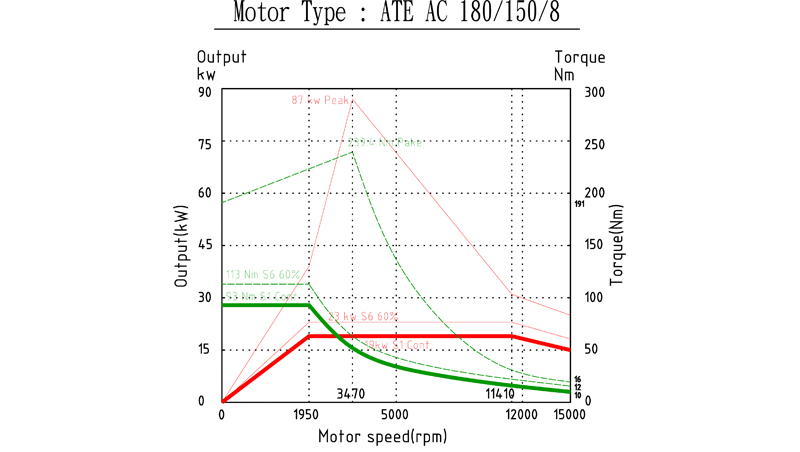

| Spindle Speed (rpm) Direct-Drive | 10000 / 12000 / 15000 | 10000 / 12000 / 15000 | |

| Draw Bar Force (kgf) | 700 | 700 | |

| Main Motor (con/30 min Kw) | 5.5 / 7.5 | 7.5 / 11 | |

| FEED RATE | |||

| Rapid Feed Rate (X/Y/Z m/min) | 24 / 24 / 24 | 24 / 24 / 24 | |

| Feed Rate (X/Y/Z/ mm/min) | 10000 | 10000 | |

| AXIS SERVOMOTOR | |||

| Mitsubishi X/Y/Z (Kw) | HF354 (3.5) | HF354 (3.5) | |

| Fanuc (Kw) | β22/3000is 3.0 (α12i/3000i 3.0) | ||

| Siemens (Kw) | 1FK7063 (2.9) | 1FK7063 (2.9) | |

| Fagor (Kw) | FKM64.30A | FKM64.30A | |

| Heidenhain (Kw) | QSY155B (2.47) | QSY155B (2.47) | |

| AUTO TOOL CHANGER | |||

| ATC Type | DISK | DISK | |

| Cam Type | DAUL ARM | DAUL ARM | |

| Tool Selection (Bi-direction) | RANDOM | RANDOM | |

| Tool Storage Capacity (PCs) | 24 | 24 | |

| Max. Tool Diameter (mm) | Ø90 | Ø90 | |

| Max. Tool Length (mm), Weight (kgs) | 250, 8 | 250, 8 | |

| MISCELLANEOUS | |||

| Air Requirement (Kg/cm²) | 6 | 6 | |

| Voltage | 220 | 220 | |

| Power Requirement (KVA) | 20 | 25 | |

| Coolant Tank Capacity (L) | 200 | 200 | |

| Machine Weight (Kgs) | 5600 | 5800 | |

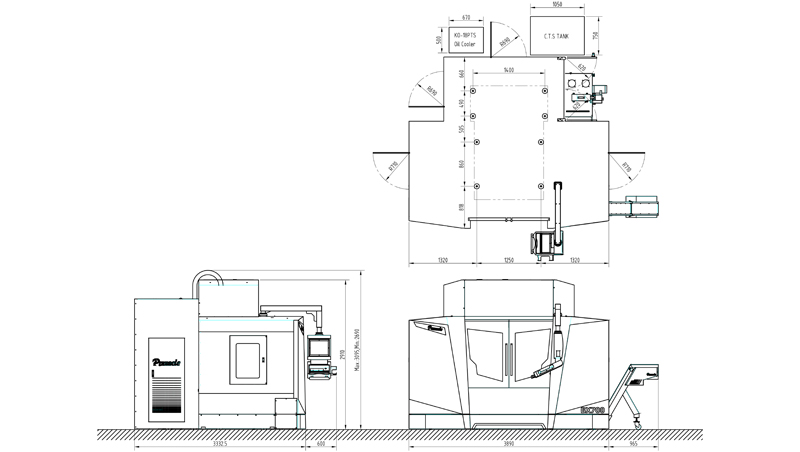

| Machine Height (mm) | 2750 | 2750 | |

| Floor Space (L x W mm) | 2600 x 2230 | 2820 x 2230 | |

| Packing Size (L x W x H mm) | 2900 x 2300 x 2450 | 2900 x 2230 x 2450 | |

All Specifications And Designs Are Subject To Change Without Notice.

Accessories

Accessories

- Air blast through spindle

- Air blast for workpiece (nose)

- Coolant flushing system

- 3 axes telescopic covers

- Full splash guard

- Centralized automatic lubrication system

- Working lamp

- Operation status light

- Cooling system

- Air gun and water spray-gun

- MPG handwheel

- Heat exchanger

- RS-232 Interface

- Rigid tapping

- Spindle oil cooler

- Adjusting tools and box

- Leveling bolts and pads

- Operation and programming manual

Control System

- MITSUBISHI M80 / M830

- FANUC 0i-MF / 31i-MB

- HEIDENHAIN TNC620 / TNC640

- SIEMENS 828D / 840D

- FAGOR 8055i Plus / 8060FL / 8060

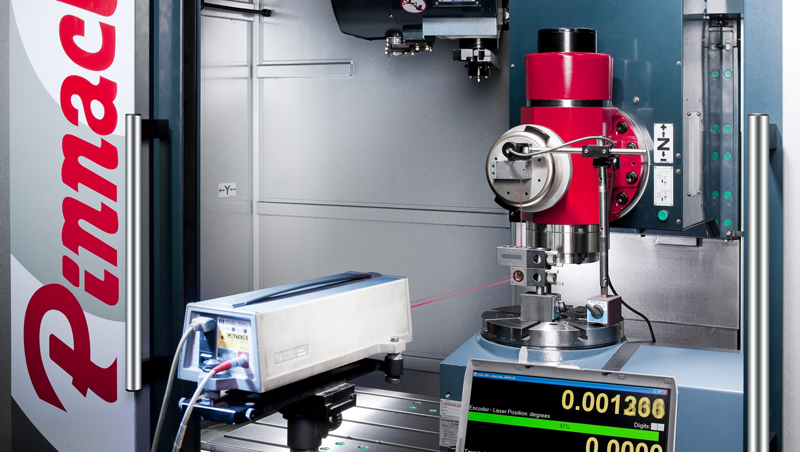

Quality Inspections

Quality Through Precision Inspections

Each Pinnacle machine is subject to dynamic and static accuracy tests.

Pinnacle machine accuracy meets VDI 3441, ISO 10791, JIS B6336 and ASMEB5 standards.

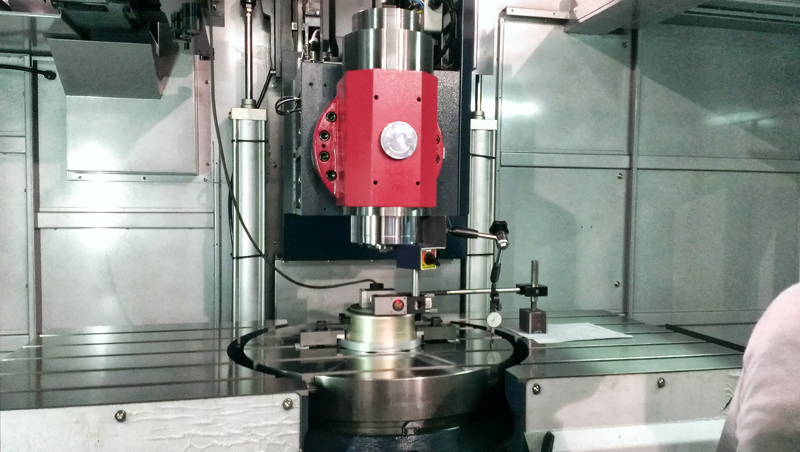

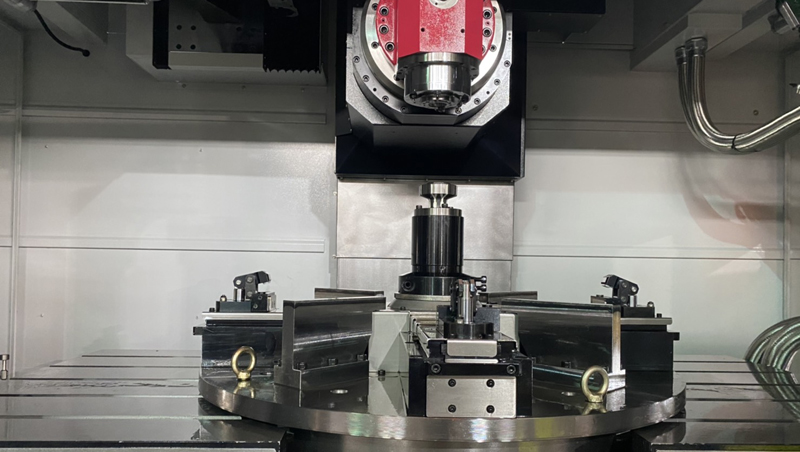

Laser Inspection

Laser Inspection

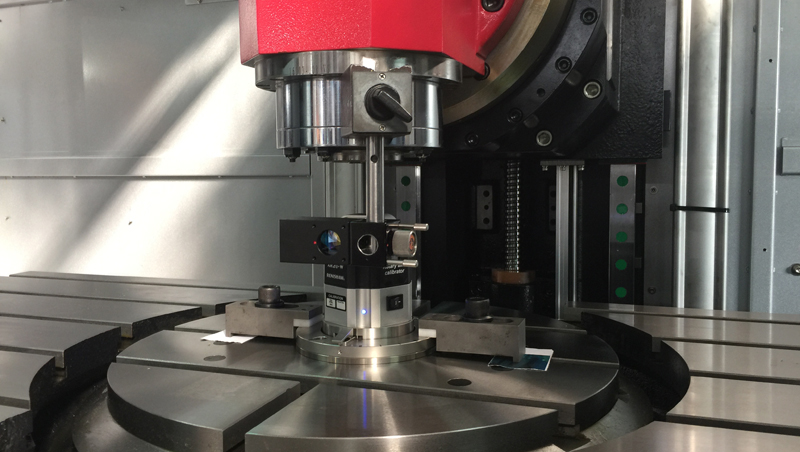

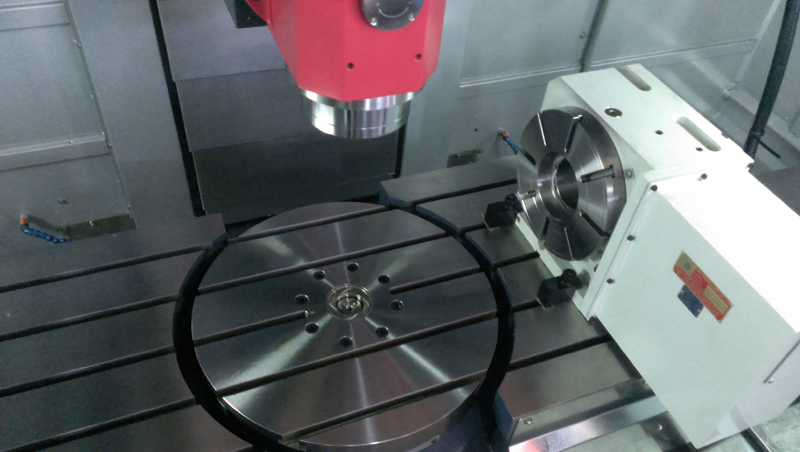

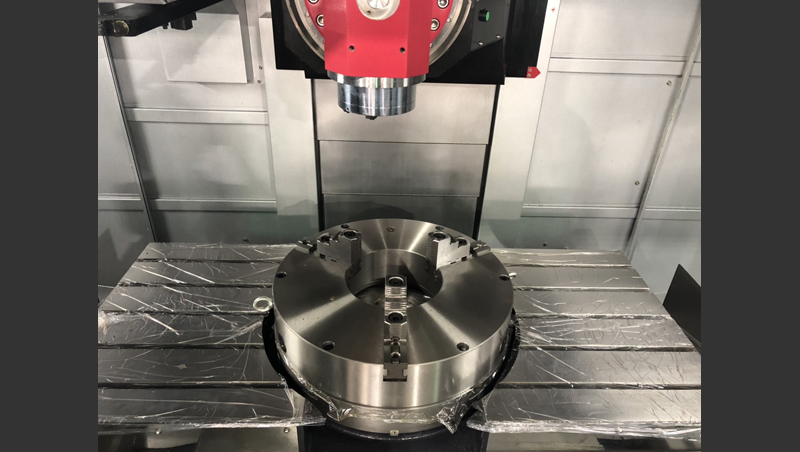

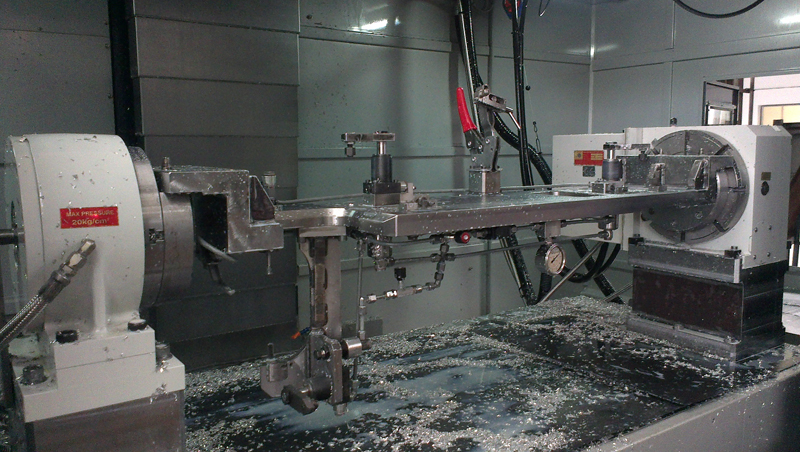

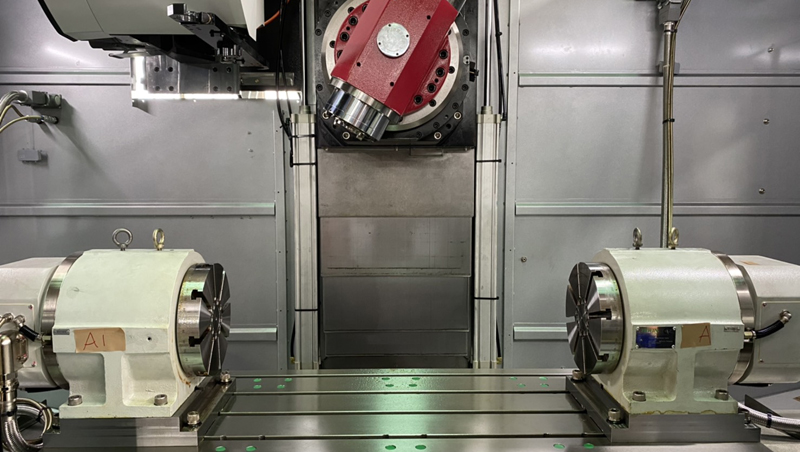

Ball Bar Inspection

Ball Bar Inspection

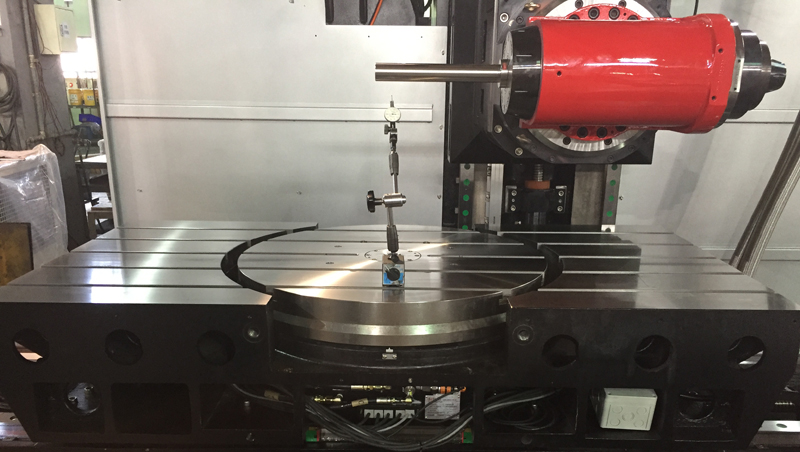

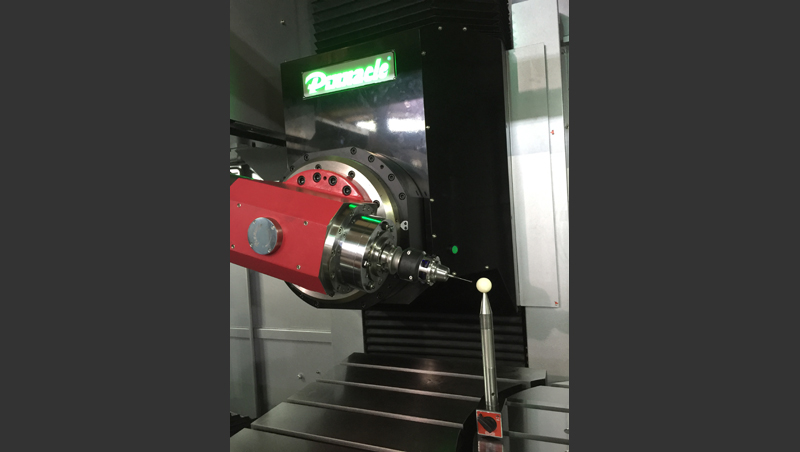

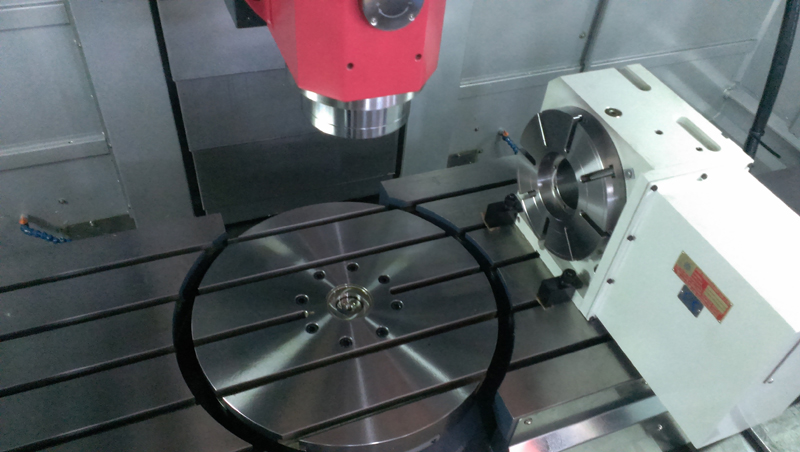

Right Angle Test On X And Y Axes

Right Angle Test On X And Y Axes

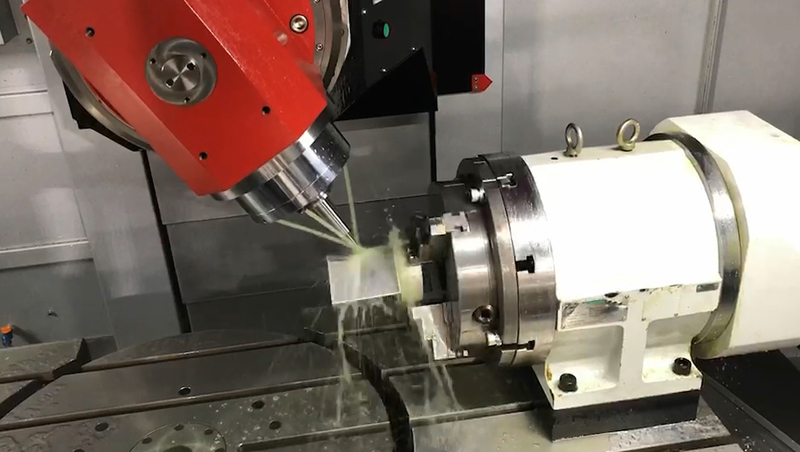

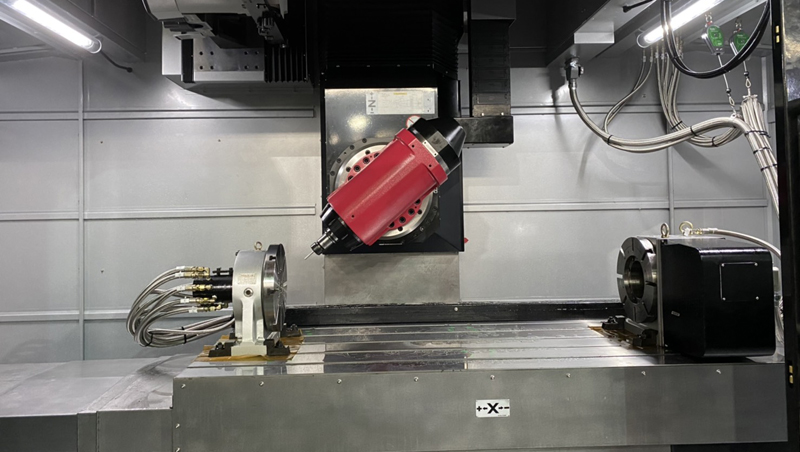

Dynamic Vibration

Dynamic Vibration

Noise Inspection

Noise Inspection

Three-dimensional coordinate measurement

Three-dimensional coordinate measurement