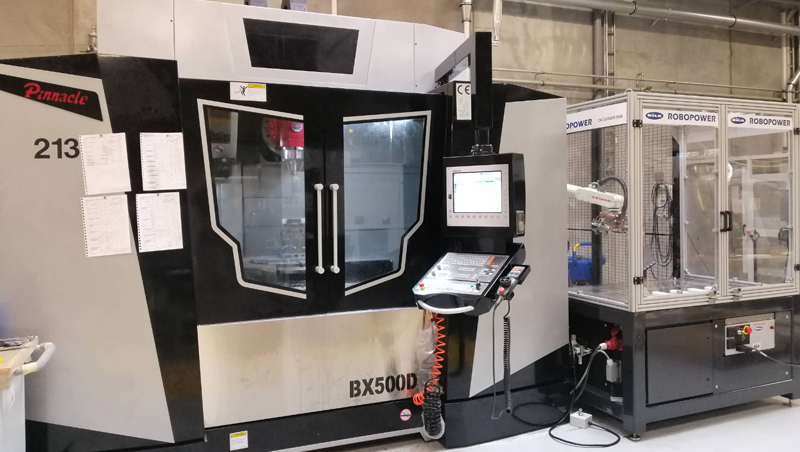

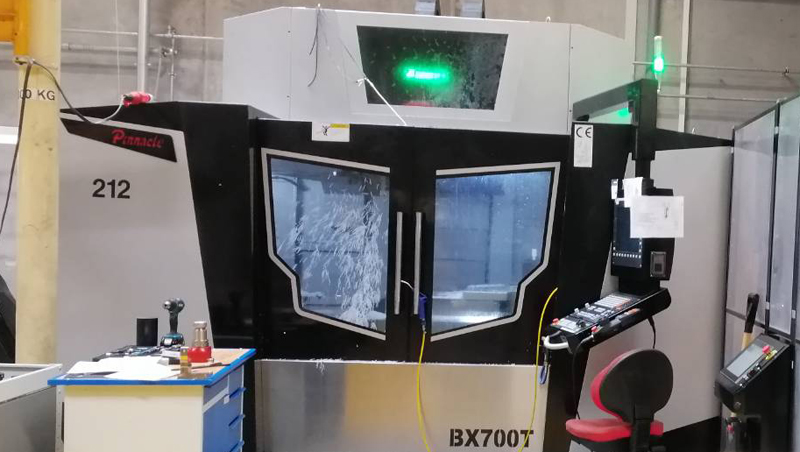

L series

L210CMY

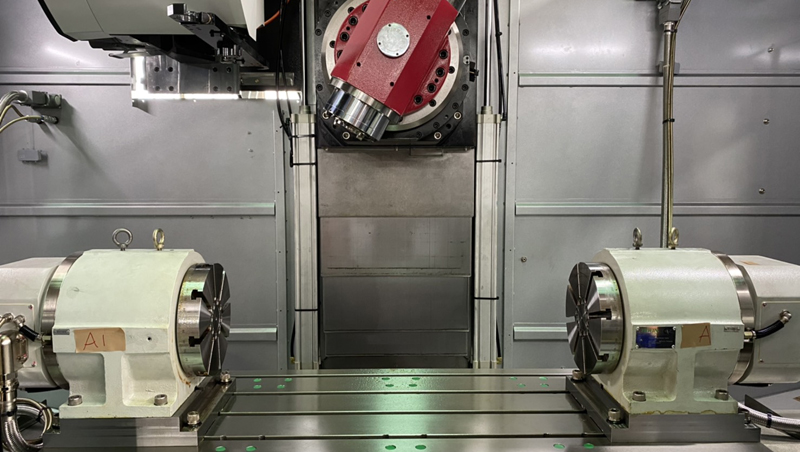

Slant Bed CNC Turning Center

WITH A PINNACLE SLANT BED CNC TURNING CENTER, YOU CAN SEE THE DIFFERENCE IN PERFORMANCE AND QUALITY.

With the Pinnacle Slant Bed CNC turning center you get full capabilities to produce the ultimate in heavy-duty turning, maximum efficiency and lifetime accuracy. You also get advanced design concepts that enable you to reduce time cycles to create more profit. When you select a Pinnacle CNC turning center, you get more than just a quality machine, you also get the Pinnacle tradition of excellence.

- Features

- Specifications

- Accessories

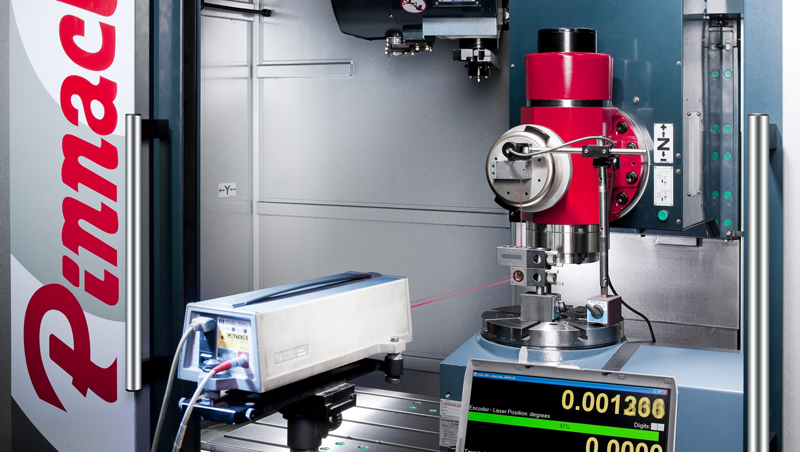

Features

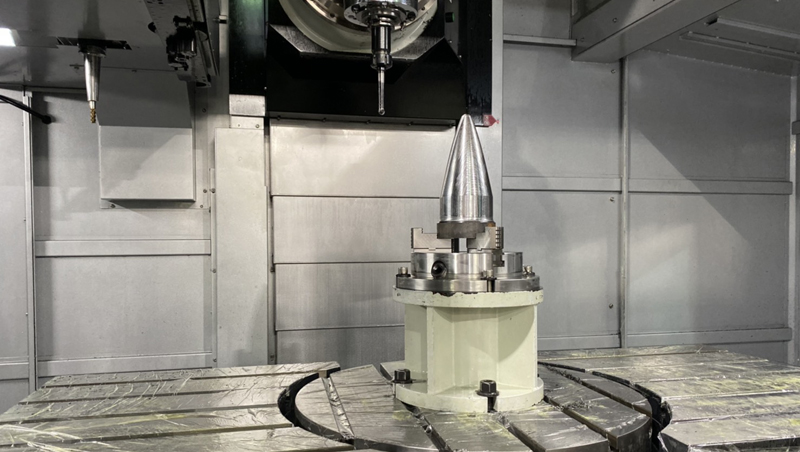

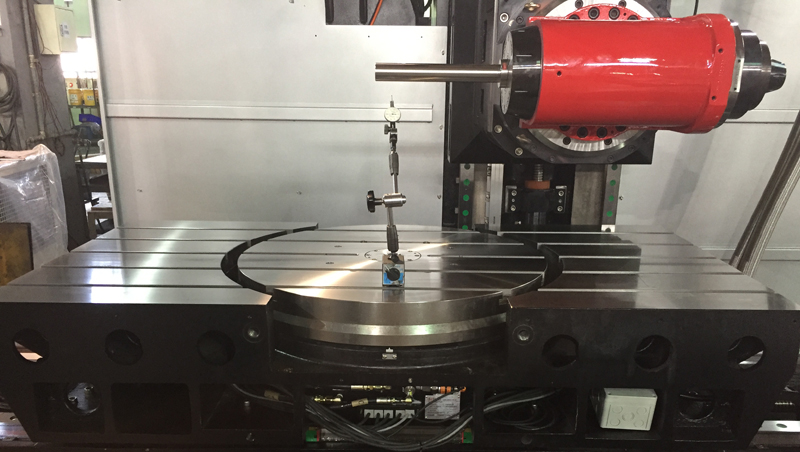

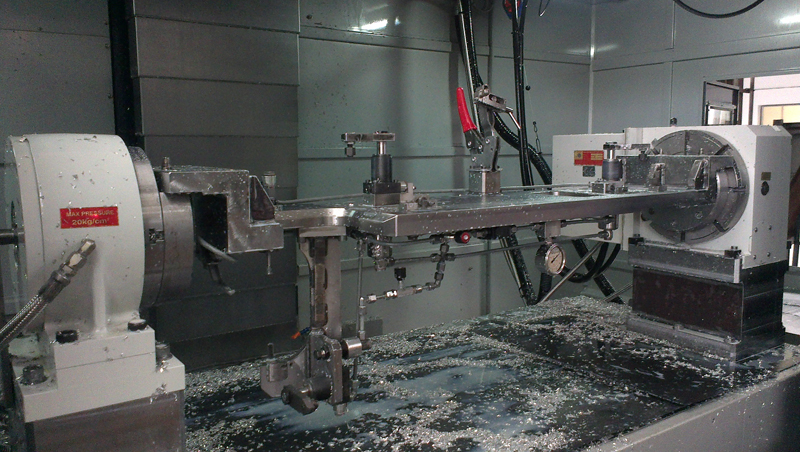

PROGRAMMABLE TAILSTOCK

Convenient and accuracy programmable tailstock is driven by saddle. Quill is driven by hydraulic and programmable as well.

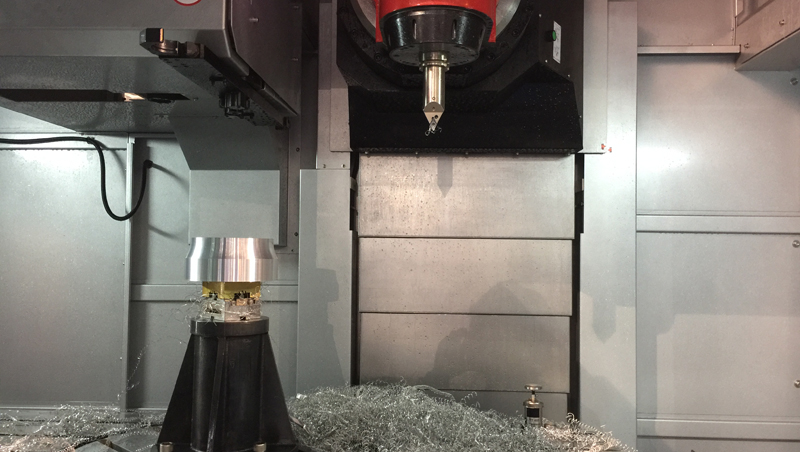

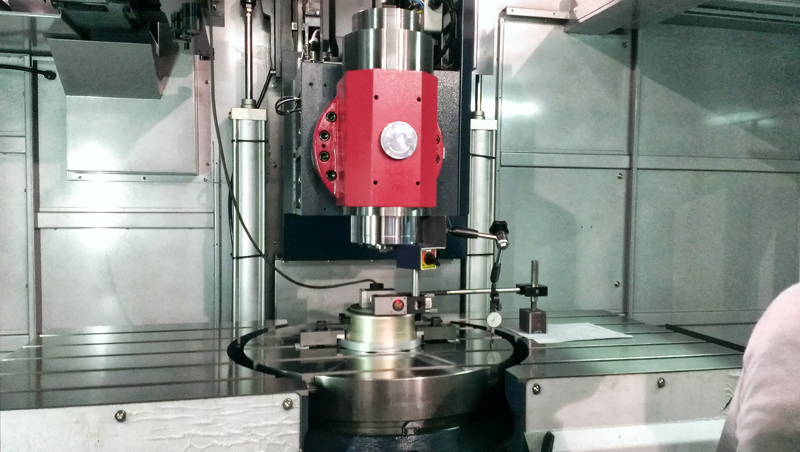

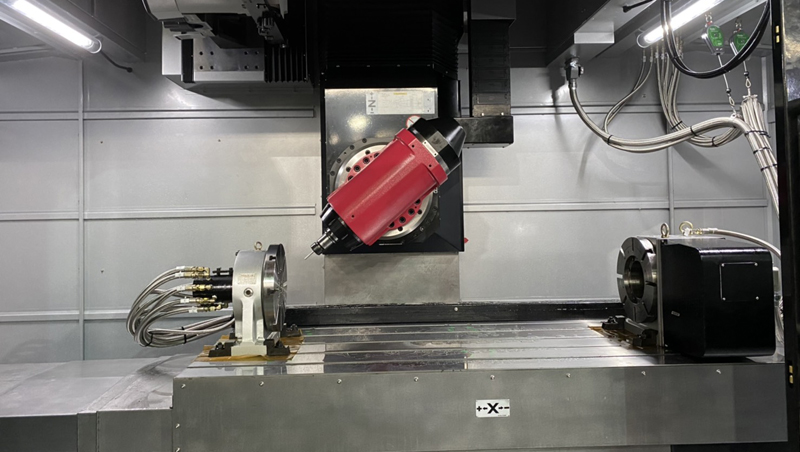

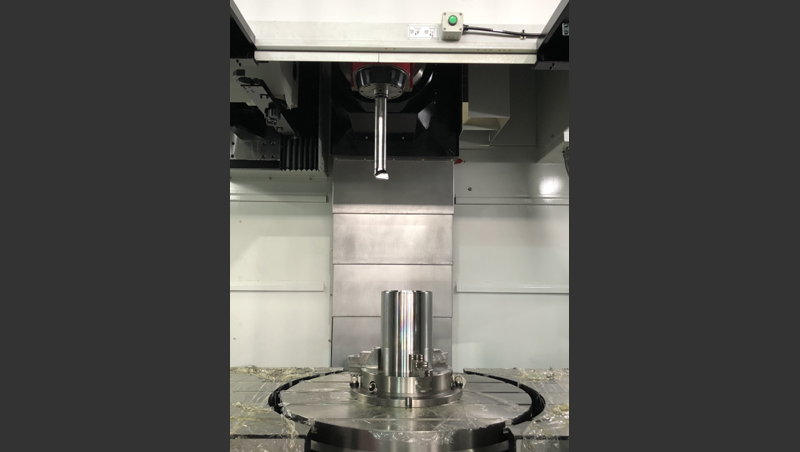

RIGID SPINDLE

Supported by superior precision high speed angular ball bearings to provide extra wide range machining capacity and increase rigidity. as well as extends the spindle bearing life.

SPINDLE HEADSTOCK

The radiation fin design and exhaust heat hole for excellent heart remove to ensure accuracy and enhance spindle life.

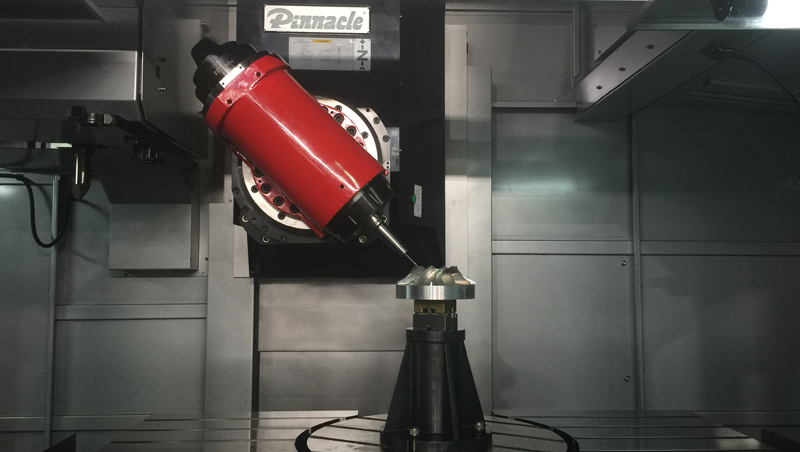

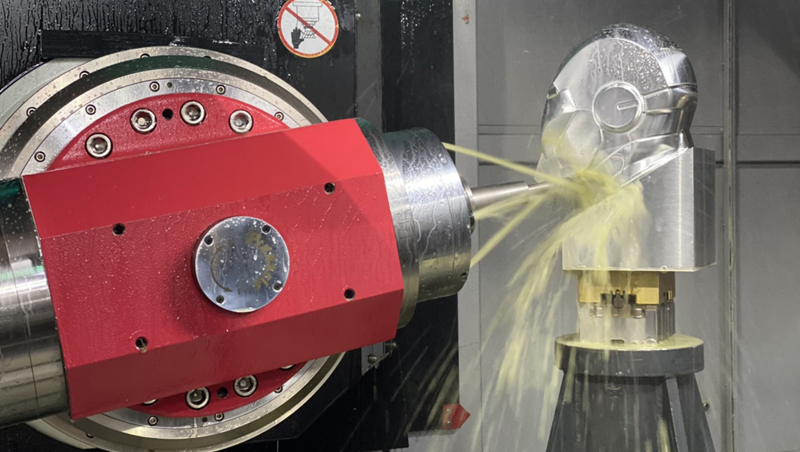

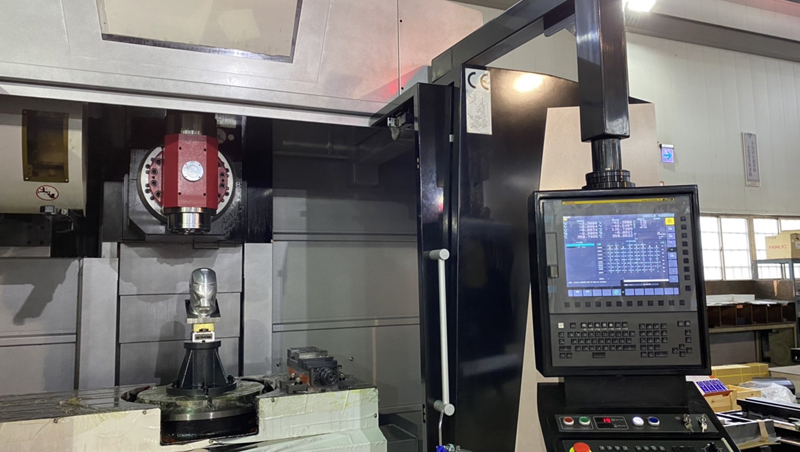

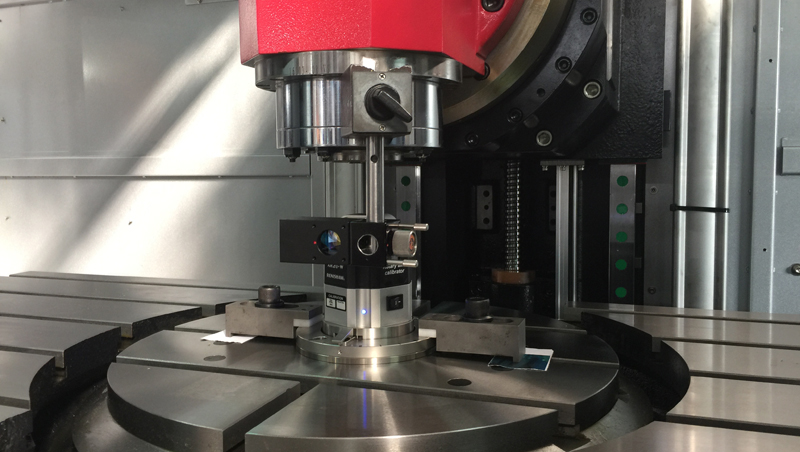

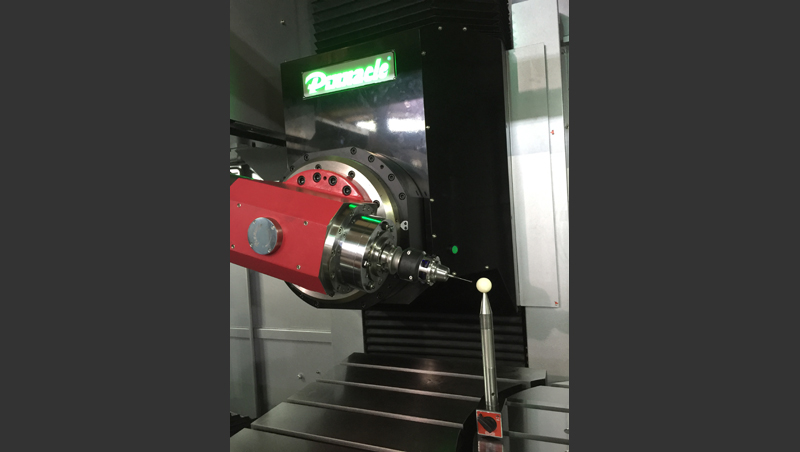

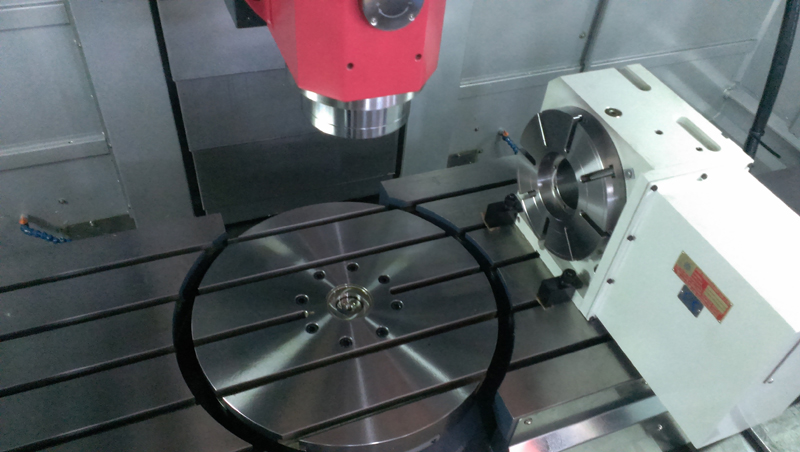

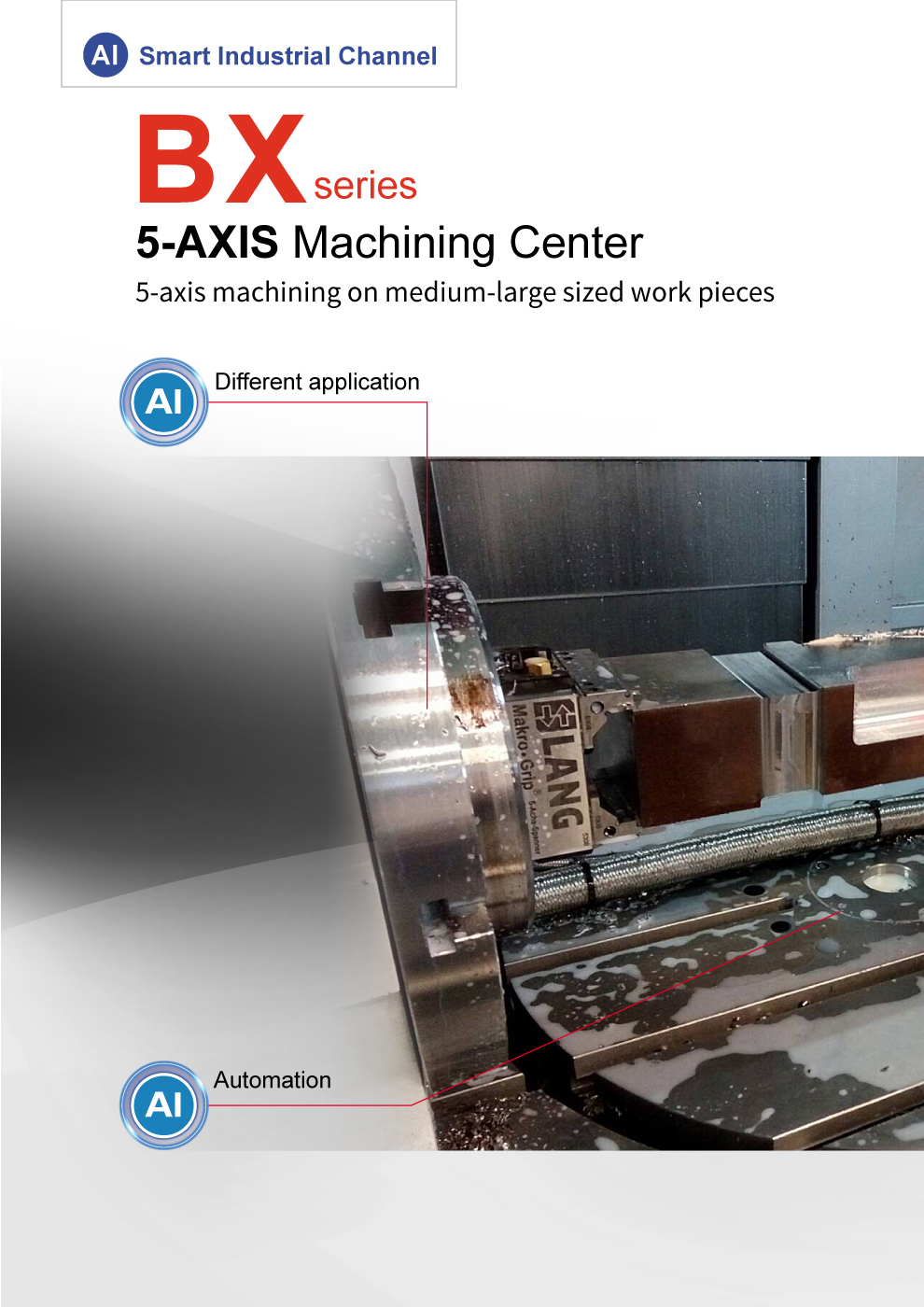

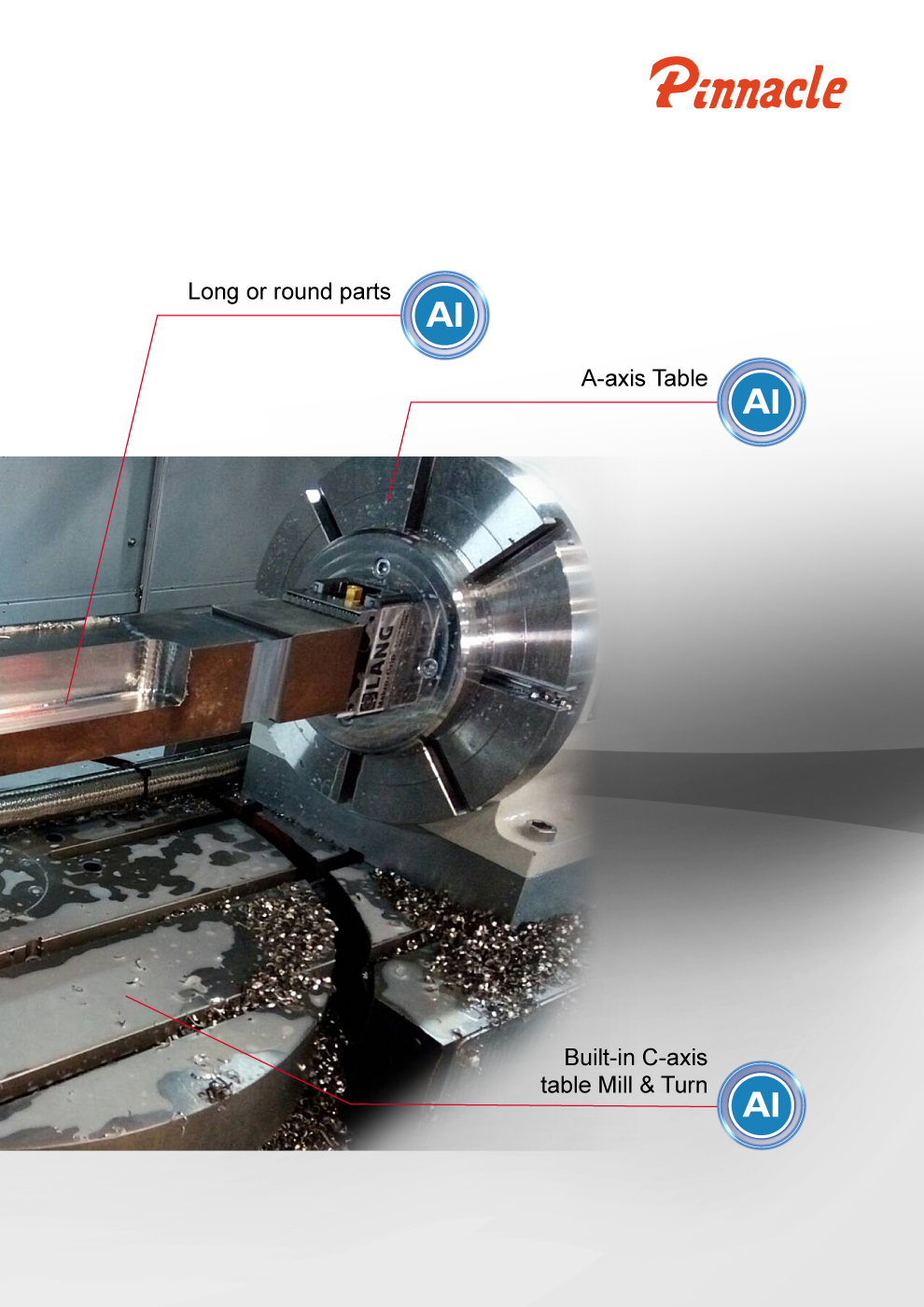

C-AXIS

C-axis 0.001 degree high accuracy position for drilling on surface on certain position. Increase turning capabilities and productivity.

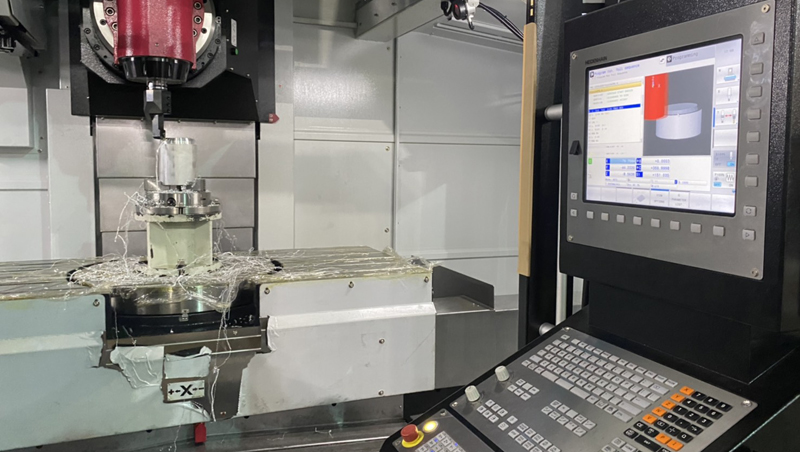

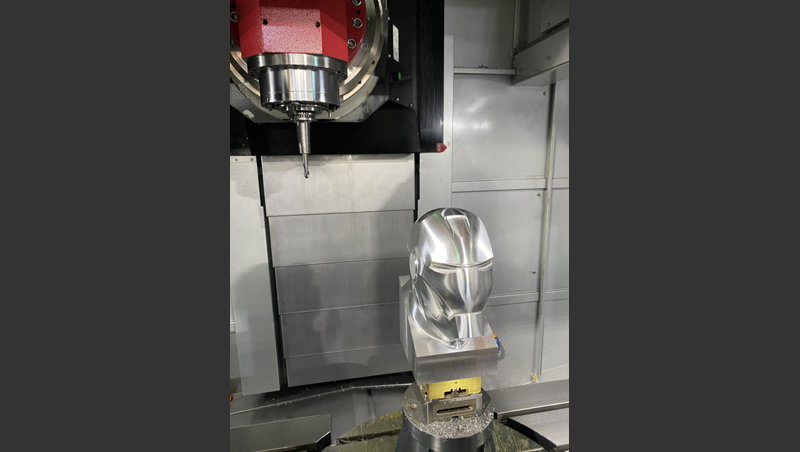

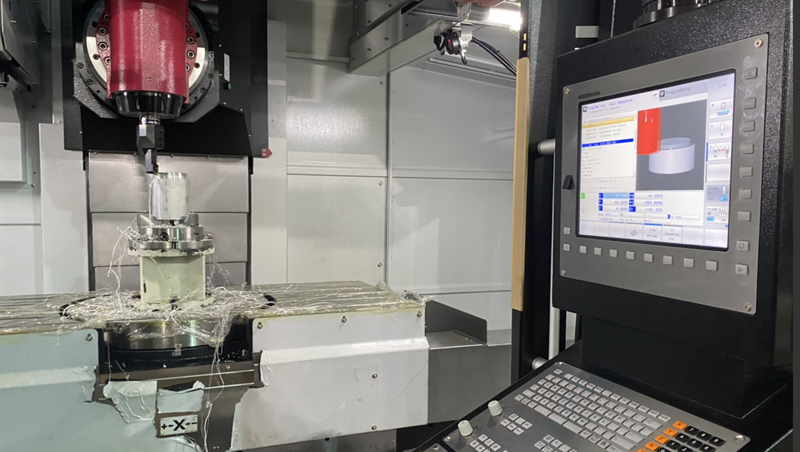

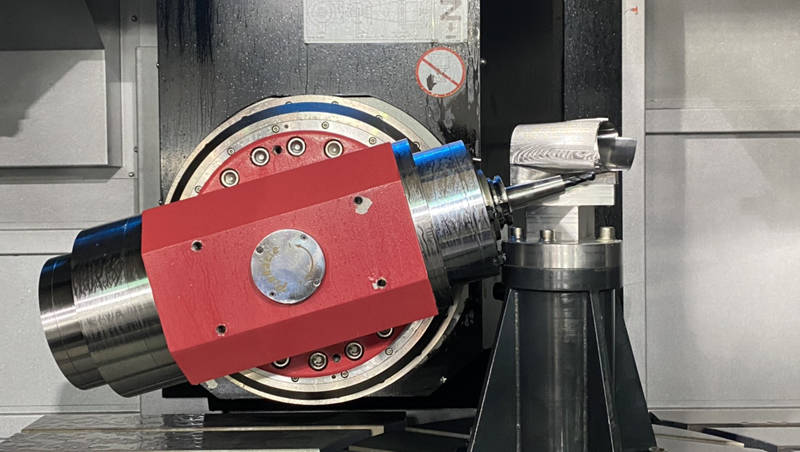

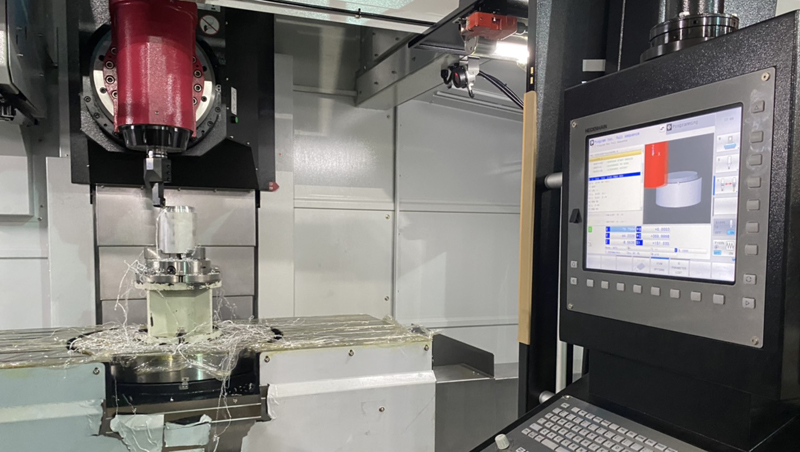

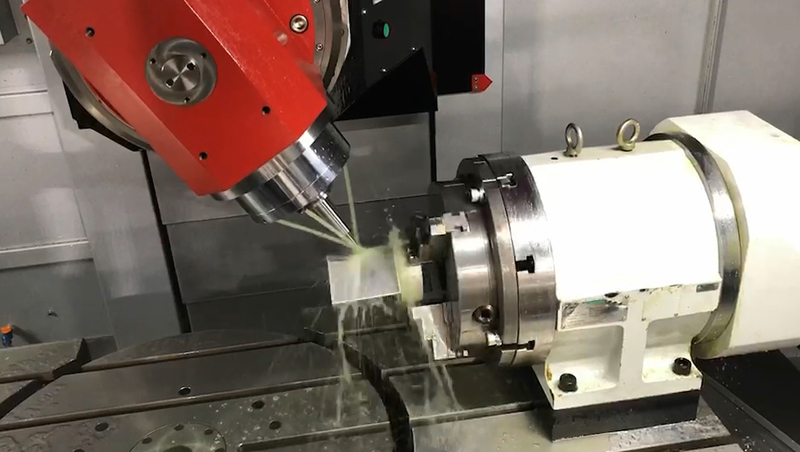

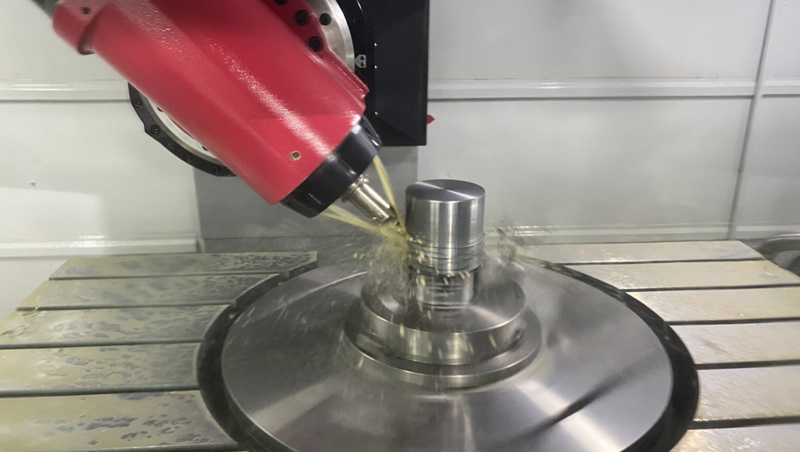

LIVE TOOL AND Y-AXIS

VDI 30 living tooling turret offers milling, tapping, drilling, turning function, with Y-axis (±40mm) for eccentric operation to reduce cutting time and operation. Best solution for complex work piece.

TOOL SETTER (OPTION)

PARTS CATCHER (OPTION)

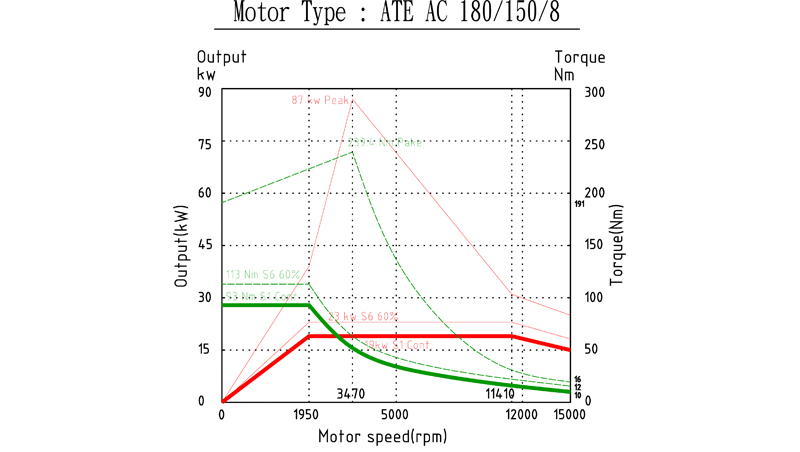

Torque Diagram

10 Station

Specifications

| MODEL | PK-L210A/BMY | PK-L210C/DMY |

|---|---|---|

| Swing Over Bed (mm) | Ø750 | Ø750 |

| Swing Over Cross Slide (mm) | Ø650 | Ø650 |

| Max. Turning Dia. (mm) | Ø330 | Ø330 |

| Max. Turning Length (mm) | 570 | 570 |

| Spindle Motor (kw) | 11 / 15 | 15 / 18.5 |

| Spindle Speed (rpm) | 45 - 4,500 | 35 - 3,500 |

| Spindle Nose | A2-6 | A2-8 |

| Chuck Dia. or Collet | 8", 10" | 10", 12" |

| Dia. Hole Through Spindle (mm) | Ø77 | Ø88 |

| Bar Capacity (mm) | Ø65 | Ø77 |

| Spindle Bearing I.D. (mm) | Ø110 | Ø130 |

| Tailstock Taper | MT4 | MT4 |

| Tailstock Quill Dia. x Travel (mm) | Ø85 x Ø80 | Ø85 x Ø80 |

| Feed Motor X/Y/Z (kw) | 2.5 / 2.5 / 1.8 | 2.5 / 2.5 / 1.8 |

| X Axis travel (mm) | 195 (165+30) | 195 (165+30) |

| Z Axis travel (mm) | 570 | 570 |

| Y Axis travel (mm) | 80 (±40) | 80 (±40) |

| C Axis travel (mm) | 0.001 | 0.001 |

| Rapid Speed X/Z (m/min) | 20 / 24 / 8 | 20 / 24 / 8 |

| Cutting Feed (mm/min) | 0.016 ~ 5,000 | 0.016 ~ 5,000 |

| Tool Stations Number on Turret | 12 | 12 |

| Turret Index Time (T-T) sec | 0.14 | 0.14 |

| Tool Size (mm) | VDI30 / □20 | VDI30 / □20 |

| Boring Tool Dia. (mm) | Ø32 | Ø32 |

| M Function speed (rpm) | 5000 | 5000 |

| Power Requipment (KVA) | Ø3, 20 | Ø3, 30 |

| Hydraulic Pump Motor (kw) | 2.2 | 2.2 |

| Coolant Pump Motor (kw) | 0.55 | 0.55 |

| Lubrication Pump Motor (w) | 0.075 | 0.075 |

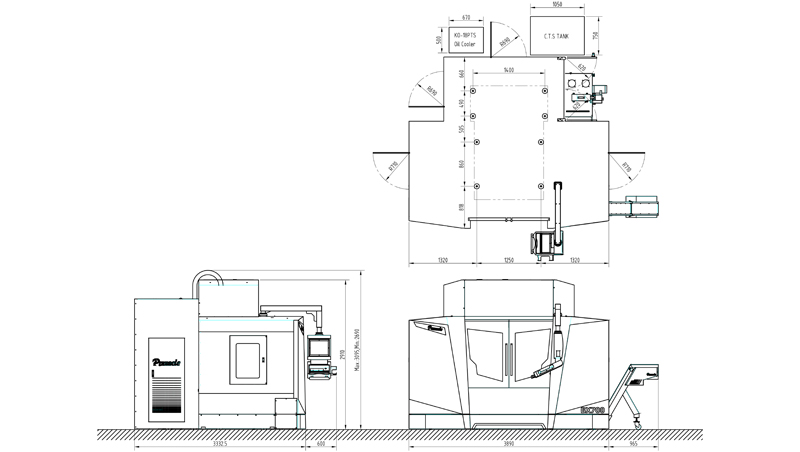

| Floor Space LxWxH (M) | 3.8 x 1.7 x 2.3 | 3.8 x 1.7 x 2.3 |

| Machine Weight (kg) | 5,500 | 5,600 |

All Specifications And Designs Are Subject To Change Without Notice.